Interview: Aston Microphones

Hollin Jones on Feb 25, 2018 in Interviews | 0 comments

Aston is an independent British company that focuses on bringing high quality and unique pro audio gear to the market at a price that's accessible to as many musicians and producers as possible. With its Origin, Spirit and Starlight microphones, Halo reflection filter and now SwiftShield combined shock mount and pop filter, the company has been winning acclaim from many users around the world. We caught up with the founder, James Young, for an in-depth chat about its past, present and future...

AA: Can you tell us a little about your own background in the pro audio world? How did you come to found the Aston brand?

JY: I spent one year in retail when I first started out, working at Turnkey in London on a commission only sales job, and with no other experience than being a musician and doing a lot of home recording myself. My educational background was a degree in Zoology, and a Masters in Gerontology… so not much to do with Music! But it did give me a good grounding in presentation, organization etc. I went from this job into distribution, where I spent almost 6 years supporting and selling Alesis, Lexicon, Aphex, Emagic and so on.

In 2002 I started a distribution company of my own, and over the years had UK exclusive distribution for brands including Blue Microphones, Waves, SPL, Apogee, Blue Sky, Primacoustic and many others. A couple of years before I started Sonic Distribution, I got involved with a Chinese agent for OEM mics coming out of Shanghai Feilo, Siwei Zou. I spent 2 years importing his OEM mics to the UK. When I started Sonic I contacted him wanting to start my own brand… Siwei had a couple of mics he’d been producing through Feilo which he wanted to turn into a proper brand. There seemed to be good synergy there, so we agreed to use these designs as a base to launch a new brand to market. That brand became sE Electronics.

My business partners and I spent 12 years building sE to a $5M global business by 2014, looking after sales, marketing and product development... basically everything aside from prototyping and manufacturing, though we were also heavily involved in testing and driving the processes at factory level to move the brand from OEM to a fully-fledged brand.

In summer of 2014 we brought up short after being told our ‘services were no longer required’. It was a hard learned lesson that contracts aren’t worth a lot when a company is based in China unless you have very good lawyers and very deep pockets!

But, like all adversities in life, it’s the way you deal with it that determines the outcome. We had such an outpouring of support from the industry as a whole, the general vibe being ‘you guys built that brand, go show everyone what you can do on your own terms’, that we decided to make the apparently mad decision to go build another mic brand from scratch… bloody glad we did too!

We treat everyone connected to the brand as an extended family. Our belief in what we’re achieving filters through on every level, and we treat customers, not as ‘units’ to be sold to, but as musicians we are supporting with great products.

In 2 short years Aston has been nominated for 2 TEC awards (the first time this has ever been achieved by a mic brand in its first 2 years), won NAMM Best in show for the brand in 2017, and countless other awards for excellence and performance. Not only that, but the brand is already up there in terms of revenue, and will easily surpass what we did with sE in our 3rd year. As they say, ‘every cloud…’

It’s funny, but the adversity of losing sE has turned out to be the best thing that ever happened in our business career. Without that, Aston would never have happened and we’d still be trying to westernize a Chinese brand on someone else’s strings. Aston has been a life changing experience for us. We’re so happy and proud to be doing what we’re doing, changing industry standards, and building a true British manufactured brand. It’s incredible, and we have an awesome team who really believe in what they are doing.

What is the philosophy behind the company and its products? You definitely place an emphasis on the fact that the products are designed and built in Britain.

Family. We treat everyone connected to the brand as an extended family. Our belief in what we’re achieving filters through on every level, and we treat customers, not as ‘units’ to be sold to, but as musicians we are supporting with great products. When it came down to starting the brand, the first thing we did was sit around a small, white, chipped melamine kitchen table in our office, with pads of paper and pens, and knock out a brief: what products we wanted, what our look and feel would be, our ethos… and this is where it landed:

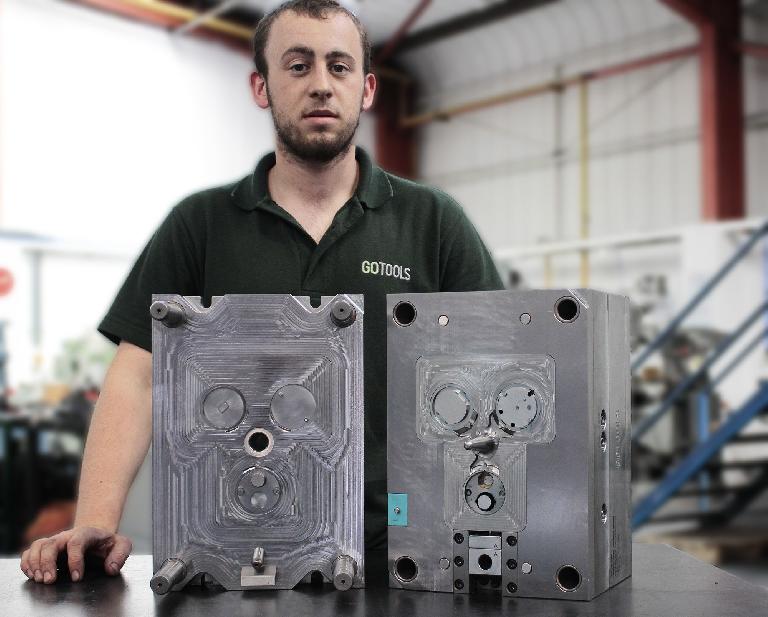

1. We MUST really MAKE the products in the UK – not just say we’re a British company and extensively lean on OEM as so many other western ‘brands’ do. This was fundamental to the project. I had wanted to make mics in the UK for years, and sE pushed back hard against both this, and USA based production. The opportunities with UK production are many, but include smaller environmental footprint, local prototyping and control of engineering processes, no language barrier, a great marketing story, etc. But most of all the reason was this - there isn’t (wasn’t before Aston) a current British mic company. Sure, there are OEM companies masquerading as British, as there are all over the world. The USA has many, and there are a couple of boutique enterprises, the most notable being Coles of course but they are only producing ribbons. Soundfield, recently bought out by Australia's Rode, were a British owned high end mic company, but nothing mainstream.

The UK is arguably one of the most formative opinion makers in the modern music industry. What an opportunity then to become the only brand to give the UK a literal voice in the same market. To have the opportunity to build a legacy which will be THE UK mic brand. Very cool!

2. Products must be innovative – we didn’t want our products to just be more of the same. There are literally 100’s of mic brands, most of them (even some of the big guns) OEM, and all delivering pretty much the same thing with some notable exceptions. We wanted to really re-think mic technology, indeed we were forced to, because if we’d simply regurgitated Neumann like so many before, then we’d have just been an expensive (compared with China) copy… another one! Boring!

3. Products must have a unique aesthetic… and not just look whacky for the sake of standing out (you know the brands I mean!!)

4. Products must be competitive with the likes of Rode.

So all of the above, and utilising UK manufacturing and labour was no small mountain to climb!

But it was exactly this which forced us to rethink how mics are built, and their every function (not just ‘recording stuff’!). Questions like, ‘what is the mesh head for, and can it be improved?

This is a good case in point. A mesh head acts as a Faraday cage, as plosive control and to protect the capsule. Certainly both the protection and pop filtering could be greatly improved on every single design ever made… you only have to note that everyone needs to buy a pop shield to see one of those points being played out. The other - protection - well if you whack the head of a studio mic, it either breaks the innards, or breaks the head itself. So not great design. But nobody ever questions it… these things fall under the heading ‘that’s just how you build a mic’.

We think differently, and it's why our mics have gained a reputation for being almost indestructible. Yet as part of that design ethic, we’ve actually vastly reduced production costs compared with the standard ‘something rigid to frame some fixed gauge mesh’ approach. We treated every single detail the same, hence our £249 mic has engraved details, a metal badge, virtually zero handling noise, doesn’t need a pop shield and so on.

So in summary, being in the UK was massively important to us on many levels, and our brand ethic stems from trying to do everything we can, the best we possibly can. Even our packaging is actually MADE in the UK. Environmental impact is hugely important to us - lots of recycled materials, greatly reduced chemical processes compared with other mic brands. If our customers are really an extended family, which is what we believe, then we have to do our best by them in every regard. Price, quality, performance, technical progress, and looking after the world we all live in while we’re at it. I’m proud to say we’ve never cut corners on this, even though we’ve been given plenty of opportunities to increase profits by doing so.

At present you have quite a focused product range. Are you of the opinion that it’s better to do fewer things but do them better?

Absolutely. For many reasons. We had a 12 year relationship with a company who insisted we release several new products every year to gain turnover, something which I personally hate! So I’ve had plenty of experience of the other end of things. But there are lots of practical reasons for a compact line:

1. Focusing on development of one product at a time means a better product. Simple as that. We were able to do more in our first year, because we were ONLY doing product development so didn’t have to worry about sales and marketing.

2. Retailers like compact brands. They hate big eclectic ranges as it’s the 80:20 rule playing out with your stock and their cash otherwise. A few strategic products ALL doing amazing numbers is every retailer's dream brand, and that’s what we have with Aston.

3. The musicians and engineers who are buying mics want to understand exactly what they are buying and why. When you have a big range it starts getting very confusing, very quickly. People like to know: this mic for this application. The truth though is that most mics can be used for most applications so if you have 20 mics in your range, it’s just plain awkward and impossible to justify for anything other than commercial percentages.

4. Marketing – how do you market 20 products? You can’t (unless you’re a massive company)! 2 or 3 is hard enough… so if you have more than 3 products, already, something is being left to fend for itself.

How do you assess the need of the market for a specific kind of product? What’s the design process, without giving away any trade secrets!

Actually assessing the need for what we’ve produced was pretty easy. 12 years of making mics within another brand gave me a lot of insight into just how much of our industry is ‘me too’ products. By breaking down each separate area of the mic and asking, ‘what function does this perform REALLY?’ we were able to identify where we could make improvements.

But our biggest break was in the sound… something we’ve come to call the Aston Sound, developed by a panel, originally, of 33 of the top producers and engineers in the UK.

In every area of product development it generally goes the same way… a marketing team puts together a brief, the engineering team executes it. But the real ‘ears’ only come in right near the end of the process to check everything is OK (or not!).

We handed the entire sound development process to our panel from day 1, and we did not influence the choices they made at all. Every PCB tweak, capsule or component change, was chosen by group blind tests over a 6 month period. The result of this process has been remarkable, in that even we would not have thought it possible to get the performance we have out of a £249 mic.

By working with the best ears in the business, right from the start, we’ve ended up with our little £249 mics being consistently compared to high end Neumann, Telefunked, AKG mics costing 10x as much. It’s quite incredible.

What do you think is the most important consideration when designing and building a mic or mic accessory?

Well, obviously for a mic it’s the sound. But weirdly, its one is the last things most customers check out for themselves. They see the marketing, they see images, they see what accessories the mic comes with, and they buy with their eyes. Frankly I wish more people would go to stores and use their ears to buy their gear. Reviews are helpful to an extent, but even customer reviews are flawed by the fact that people make buying choices made on volume of good reviews.

The musicians and engineers who are buying mics want to understand exactly what they are buying and why. When you have a big range it starts getting very confusing, very quickly.

Simply put, a well-funded company can spend a lot on marketing, and will sell a lot of product. When customers have invested in buying a product, they will most likely give it at least a good review unless the product is truly crappy. Does this tell you whether one product is better than another? Absolutely not. What is distinctive about Aston is that our mics are never compared with products in the same price range in independent reviews… that says a huge amount about our sound. But still... I want people to go listen before they buy! A mic is the first point, and the most important limiting factory, in every single recording ever made. It should be listened to and understood before buying. After that, reliability and looks of course.

Can you talk us through the design of the Spirit model? What does it offer that’s unique?

I guess I covered much of this above… the sound and some of the design process. There are a number of key mechanical advantages over ALL other mics.

- 1. Waveform mesh head – offers way better protection for the capsule than any other mic.

- 2. Knitted stainless steel mesh head – much better plosive control, means you don’t need a supplementary pop shield for most apps.

- 3. Almost zero handing noise – means you don’t need a shock mount and can actually hold the mic and sing into it to capture really full blown emotional performances.

- 4. Direct to stand mounting built in (as a result of the above this actually works, and looks way better!)

- 5. No paint job – reduces environmental impact, looks better, doesn’t fingerprint, scratch and heavy use resistant.

The Spirit, uniquely, also uses a toroidal transformer, which was designed and manufactured in the UK. The use of this as opposed to commonly used block (oxo cube style) transformers was yet another choice made by the panel (although they didn’t know that’s what we were playing with as we didn’t tell them anything!). Turns out it just added something to the sound which they universally loved. The Spirit’s really open and harmonic rich top end owes a lot to this choice. Maybe that’s why a mic costing only £349 is Noel Gallagher’s lead vocal mic these days… amongst many, many others!

The Starlight is obviously quite a unique product with its laser guides. How did the idea for that come about?

A drunk night out in a New York bar! We were trying to think of ways we could actually stick to our brief of making interesting technical improvements, on something as boring as a pencil mic (let’s face it.. they are aren’t they) – when after about the fourth White Russian, I was reminded of a conversation I’d had with Paul White years ago about laser guided mics. BAMM! I’m an acoustic guitarist, and stereo mic’ing is a regular bane. I HATE people cutting, time stretching, pitch correcting my stuff so it’s get a perfect take or do it again. Which is fine, so long as nothing changes… but if you need to drop in because someone has re-done a drum part etc, then getting the exact same sound again is a very time consuming process. That was the original concept, but of course it's moved on a lot from there, to ease of set up for overheads, to swift recall in live set ups and beyond.

Actually though the most important features, as is so often the case, aren’t the obvious ones. The sintered head is a massive technological leap for a mic. We’re the first company to ever use this process to actually tune the space around the capsule - others have used it aesthetically, like the AKG D190, but we’ve taken the process to a new level. It’s also given Starlight near perfect off axis linearity. Another Aston first.

Then there’s the voicing switch – no simple EQ here, but 3 custom designed circuit paths effectively giving you 3 really high-end mics, all wrapped up in a pencil mic chassis.

What kind of feedback have you had from users about Starlight and how they are using it in real world situations?

The feedback is incredible… they are on tour with Muse and Radiohead for example, and being used extensively in the studio with everyone from King Crimson to Capital FM. Everyone loves them, and is astounded by the performance. I even had a major UK producer recently tell me he’d sold his vintage Schoepes after realizing he was getting better results with Starlight!

The thing is they are so flexible. Equally at home on tour or in the studio, 3 sound variants, the laser for set up and recall… it’s such a huge package for the money. King Crimson producer, Chris Porter (also David Bowie, George Michael, Chris de Burgh etc) used them for Crimson’s 3 drummers both in the studio and currently on their world tour. Aside from all the obvious applications already mentioned, he told me how useful it was to be able to come into a studio session, power up the kit and be immediately able to SEE that nobody had knocked a mic out of position overnight. It’s the little things that make a big difference.

What are the challenges of being an independent company when the market can be dominated by big companies? Or are bespoke mics a bit of a special case? There are some successful smaller companies doing very well.

Money. We’re not a tiny one man band making custom mics in a backyard den… then, no, you don’t have to compete with the big boys. But we are most certainly in their market, and they know about it. We’ve had one major company actually canvas our USA dealers and some EU distributors, and try and shut us down, threatening to pull their products from major customers if they stocked ours! That sort of stuff, sadly, goes on a lot. But you have to just take it as a compliment and get on with it.

But even without that, the mega scale of marketing investment that these companies operate with puts us on a far from level playing field. It’s a minor miracle, and testament to the sheer quality of what we’re producing, that we’ve managed to grow to $4Million turnover annually within 2 years… still, to put that in perspective, the big guns are 10x that size. We have a long way to go but word of mouth is serving us incredibly well right now, plus rave reviews from publications like Ask.Audio of course!

Companies usually can’t give away too much about their future plans, but can you give us any insights into what products you’re working on at the moment?

We will be releasing some new accessories at NAMM 2018 and have 2 new mic products in development for release 2018 and 2019… they all follow the same ethic. Unique design, progressive technology and will go through the same A33 panel testing as our other products, to ultimately deliver performance which punches way, way above their weight. Can’t say what they are though, or I’d have to kill you!

Do you have any plans to cross over into the world of iOS-compatible mics, or are you plans strictly focused on studio gear?

For now, studio, live and broadcast. We’re staying well away from anything digital for the foreseeable. We simply don’t have the budgets to keep up in these areas... in analogue, a great product can last up to 10 years - in digital, a year is good! We’ll stick to building amazing products which will last you a lifetime I think. It’s a more fulfilling role.

Learn more about Aston mics: http://www.astonmics.com/

Learn more about recording techniques: https://ask.audio/academy?nleloc=category/audio/topic/audiorecording

.jpg)

© 2024 Ask.Audio

A NonLinear Educating Company

© 2024 Ask.Audio

A NonLinear Educating Company

Discussion

Want to join the discussion?

Create an account or login to get started!